Original Jaguar XK 120, 140 and 150 thermostats.

Jaguar applied a “Bellows”-type of thermostat with moving sleeve for all of their early XK engines. Jaguar initially used two different thermostat types, provided by either Smiths or British Thermostat where the latter type was stopped fairly soon after production of XK engines had started (see below). It remains unclear whether Smiths actually manufactured these products themselves or that they were purchased from Quinton-Brivec of Colwyn Bay (North-Wales): the construction of the two brands looks very similar. AC of Dunstable (UK) was another manufacturer of thermostats, but with a clearly different construction.

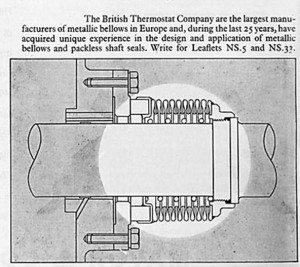

The “British Thermostat” version was only fitted to Mark VII engines (numbers A2001 to A6000) and this thermostat is non-interchangeable with the Smiths version. The British Thermostat Company (also known as Teddington) manufactured all sorts of thermal control equipment, mainly based on the use of seamless metallic bellows. From 1934 onwards they also manufactured car thermostats in their factories at Windmill Road, Sunbury-on-Thames, Middlesex. Brtish Thermostats was the largest manufacturer of seamless metallic bellows in Europe and must have supplied many other manufacturers of these bellows type of thermostats.

British Thermostat Co. was a large supplier of bellows British Thermostat version was dome-shaped

British Thermostat Co. was a large supplier of bellows British Thermostat version was dome-shaped

The American Weston Miller Fulton (August 3, 1871 – May 16, 1946) is considered as the inventor of the bellows thermostat. The invention dates from the beginning of the 20th century, intended for use in heating systems. Around 1920 they were used to control radiator shutters in automobiles and in the Thirties as a thermostat for coolant in automobiles.

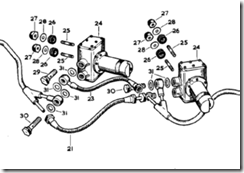

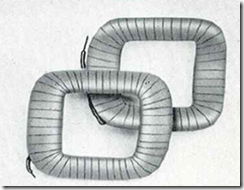

This type of thermostat has a bellows made from e.g. berylium copper or bronze and has been filled with (liquid) alcohol or volatile oil. The set point temperature of the thermostat is determined by the boiling point of the used liquid in the bellows. The Bellows-type of thermostat relies therefor on expanding gases within the bellows when the temperature of the cooling fluid rises. The moving sleeve around the outside of the lower portion of the thermostat blocks off the bypass port in the inlet manifold to optimize the flow of coolant through the engine, once the engine has warmed up and the thermostat has fully opened. It will be clear that other types of thermostat without a moving sleeve will negatively affect the warming-up periode of the engine.

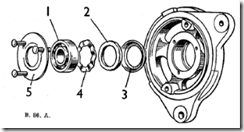

Original Smiths bellows-type thermostat Detail of “valve stem guide”

Original Smiths bellows-type thermostat Detail of “valve stem guide”

Bellows thermostats were first introduced in 1937 or 1938. A so called “bi-metal coiled system” (also supplied by Smiths) was applied before the introduction of Bellows thermostats. Smiths bellows-type thermostat types were used on many cars throughout the 1940s and 1950s: BMC, Ford, and many others used them for their engines with by-pass cooling system. Bellows thermostat production ceased in 1960 or 1961. The more typical wax pellet type thermostats were substituted.

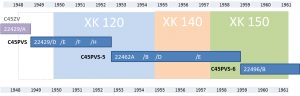

Smiths bellows type thermostat on XK 120, XK 140 and XK 150.

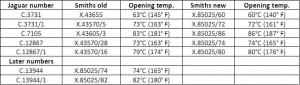

Smiths initially offered three ranges of Bellows-type thermostat: the 43570 series, 43605 series and 43655 series. They all commenced opening at a certain temperature (indicated on the thermostat) and had fully opened about 15 to 20°C higher than the opening temperature. The maximum valve lift is about ⅜” (or 9,5 mm).

XK 120

The XK 120 without a heater used Jaguar code C.3731 which is a Smith’s thermostat bellows type, part number X.43655 with an opening temperature of 60 to 63°C and has fully opened at 80°C. The XK 120s provided with a heater used thermostat Jaguar code C.3731/1 or Smiths X.43570/5 with an opening temperature of 73°C (163° F). Smiths X.43570/28 seems to be identical to X.43570/5 but is probably a later version. The XK 120 thermostat is placed in the inlet of the radiator. The outer diameter of the thermostat is 54 mm (2⅛ inch). The sleeve measures 48mm in diameter and 15mm in depth.

Smiths X.43570/7 starts opening at 75 °C (167 °F) Smiths thermostat X.43570/28 opens at 73 °C (163° F)

Smiths X.43570/7 starts opening at 75 °C (167 °F) Smiths thermostat X.43570/28 opens at 73 °C (163° F)

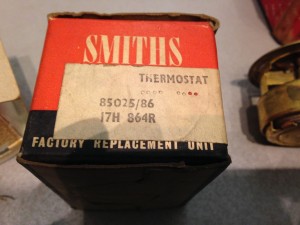

Smiths X.43570/28 with 73°C (163° F) opening temperature as “Factory Replacement Unit” (FRU)

Smiths X.43570/28 with 73°C (163° F) opening temperature as “Factory Replacement Unit” (FRU)

XK140

For the XK 140 engines, the thermostat was moved to the water outlet of the cylinder head. In March 1955 (engine number G2841) Jaguar announced that a new thermostat was fitted coded C.3731/1 (Smiths X.43570/5) but this version was already applied on the XK 120’s with a heater. Also reference X.43570/28 is used by Jaguar for C.3731/1; this version has an opening temperature of about 73°C (163° F). This old thermostat Smiths 43570 thermostat with an opening temperature of 60°C was no longer used. An alternative (winter) version carried Jaguar code C.7105 (Smiths X.43605/3) with an opening temperature of 83 (181° F).

XK150

The XK 150 range had yet another Smiths bellows-type thermostat with Jaguar code C.12867 having an identical opening temperature of 73° C (163° F) or C.12867/1 with an opening temperature of 80° C (176° F) for extreme winter climates. The corresponding Smiths numbers are not exactly known. Jaguar C.12867 for the Jaguar Mk 2 versions refers to Thermostat 02-0013 (which is an unknown brand code) and has an opening temperature of 70 to 75° C.

Change of part numbers and a (slightly) larger thermostat diameter

The Smiths coding system changed in early 1958 whereby the X.43xxx numbers were replaced by X.85xxx numbers, some with and others without the X prefix. Jaguar Service Bulletin No. 235 of January 1958 informs dealers that a new thermostat version has been introduced that has an increased outer diameter. Although this increase of .010″ or 0.25 mm is rather small, Jaguar changed the “Water Outlet Pipe” (or thermostat housing) for (all?) XK engines as there was “a possibility of the movement of the thermostat being restricted by the smaller bore water outlet pipe“. Note that SB 235 contained an error (wrong Smiths number quoted for old and new version) that has been corrected in SB 239 of February 1958 (although it contained a new typing error: X.85024/74 instead of X.85025/74).

It is therefore possible that the later Smiths thermostats with part number (X.)85025/xx may touch the walls of the older water outlet pipes. However, if you thoroughly clean the old water outlet pipes with sandpaper you will remove easily .010″ or 0.25 mm. Using older thermostats (X.43570/xx) in later pipes remains always possible.

Apart from the diameter, also the overall height of the later Smiths thermostats changed. The early X.43570 thermostats measured about 2 inch (51 mm) whereas the later Smiths thermostats with code X.85025 measured about 1 13/16 inch (46 mm). The screen (blocking the by-pass) still moved to the correct position. This implies that the later Smiths thermostat used a different bellows system that would expand over a shorter distance given the same temperature rise. Note that AC manufactured bellows thermostats show a certain (constructional) resemblance with the later Smiths versions, having an overall height of about 1¾ inch (44 mm).

Smiths X.45370 (left) is taller than X.85025 (right).

Smiths X.45370 (left) is taller than X.85025 (right).

Smiths thermostats initially had green boxes with “Motor Accessories” pinted on the sides. Later Smiths made a dedicated blue & purple box for their thermostats using the name Smiths “Superstat” printed on the box: thermostats packed in these boxes still have the X prefix for the 85025 number. Around 1960 a new orange packaging was introduced.

We also observed Smiths thermostats in a FRU packaging in red & black. These “Factory Replacement Units” also have sometimes the BMC code printed on the box label.

Note: the term “Superstat” is only used for a short period by Smiths. Stant (USA) still use the term “Superstat” for their thermostats.

Note: there were more Smiths thermostat-temperature versions available than the ones Jaguar had chosen. They are sometimes close to the nominal value Jaguar opted for. Examples: 85025/70 instead of 85025/74.

Survey of Smiths old and replacement part numbers:

Smiths bellows type of thermostat survey.

Smiths bellows type of thermostat survey.

Smiths part X.85025/70 in original green box

Smiths part X.85025/70 in original green box

Smiths X.85025/74 in “Smiths Superstat” box

Smiths X.85025/74 in “Smiths Superstat” box

Smiths part X. 85025/70 in later orange box

Smiths part X. 85025/70 in later orange box

Smiths 85025/74 in orange box

Smiths 85025/74 in orange box

Smiths part X.85025/86 in orange box

Smiths part X.85025/86 in orange box

Later Smiths Factory Replacement Unit (FRU) packaging with 85025/86 winter thermostat

Later Smiths Factory Replacement Unit (FRU) packaging with 85025/86 winter thermostat

Other brands with replacement thermostats for XK engines

Original Smiths’ bellows type thermostats are difficult to find these days. After Smiths ceased production of this type of thermostat, the following brands became (and occasionally still are) available:

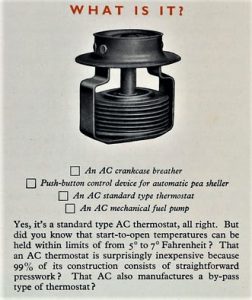

1. AC-Sphinx and AC (DELCO)

2. Lucas (Motostock) (made by AC Delco)

3. Quinton Brivec / Quinton Hazell (made by Quinton Brivec)

4. Remax (made by Quinton Brivec)

5.GH thermostats (made by Quinton Brivec?)

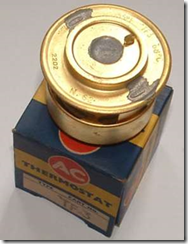

Survey of AC branded bellows type thermostat with screen

In 1952 AC Sphinx Spark Plug Co in Dunstable changed its name to AC-Delco, becoming a Division of General Motors Ltd. The Dunstable plant closed in early 2003, by then occupied by Trico Products. Also manufacturing facilities in Southampton. Main Office AC Delco at Stag Lane, Kingsbury, London NW9 OEH. The AC Delco company delivered a.o. thermostats to many UK car manufacturers beside Jaguar. See also the adds below dating from 1954 and a pre-1952 bellows thermostat still branded AC-Sphinx .

After WW2 AC Sphinx supplied two ranges of “bellow-type” thermostats: TC series without sleeve and the TF series with sleeve or as AC called it in a 1948 advertisment: “the by-pass type of thermostat“

AC Sphinx adverisement of Aug 1948

AC Sphinx adverisement of Aug 1948

Four different TF versions were manufactured and each one had an internal manufacturing code (next to the commercail code and the temperature stamped on the top). These numbers can be used as an additional check.

- TF-1 72° C 2235, 2663

- TF-2 80° C 2233, 2664 and later 2310

- TF-3 68° C 2202

- TF-4 86° C later 2307

Different types of AC packaging are known: four are shown in this overview. We assume that the oldest packaging is printed in blue and yellow with the AC logo in red (see TF-4). Then there is a packaging without the yellow accent (see TF-1 LH photo), followed by white and blue packaging still AC branded (see TF-2 RH photo). The fourth type has AC Delco printed on the box (see TF-1 RH photo).

AC (DELCO) No TF-1 thermostat (replacing Jaguar code C3731/1 which had an opening temperature of 70° C). Opening temperature: 72° C (158° F) summer thermostat.

AC TF-1

AC TF-1

AC (DELCO) TF-2 thermostat (intermediate solution between Jaguar code C3731/1 and Jaguar code C7105). Opening temperature: 80° C (176° F) winter thermostat with manufacturing code 2310. TF-2 thermostats were available in a box or packed in a blister.

TF-2

TF-2

AC (DELCO) No TF-3 thermostat with opening temperature 68° C (155° F) for “hot climate” conditions

AC (DELCO) TF-4 thermostat (replacing Jaguar code C7105 with opening temperature at 83° C). Opening temperature: 86° C (186° F) as winter thermostat.

The RH photo is interesting as it shows a TF4 stamped thermostat with a 68° C temperature which should have been 86° C !! The production code 2307 is however correct for a TF4 version. After checking it turned out to be a correct TF4 thermostat as it started to open at about 84° C. Probably this whole production batch had this error, so you have been warned…

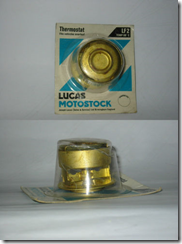

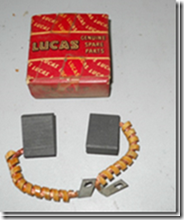

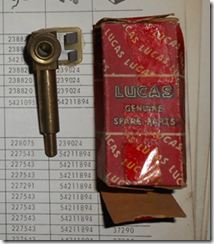

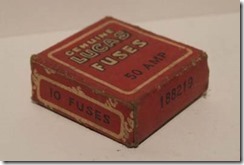

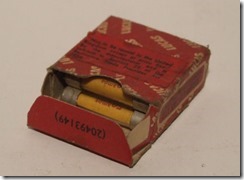

Survey of Lucas (Motostock) (made by AC Delco)

In the 1980s the automotive activities of Smiths had been sold to Lucas and later to a group of factory employees. This probably explaines that Lucas started selling Smiths thermostats, although they were most likely made by AC Delco of Dunstable (UK).

Lucas LF1

Has an opening temperature of 72° C (160 F) and has the correct screen around the bellows

Lucas LF1 in early packaging type

Lucas LF1 in early packaging type

Lucas LF2

This version has an opening temperature of 80° C (176 F) as winter thermostat. This version has the correct screen around the bellows.

Lucas LF2 in later packaging type

Lucas LF2 in later packaging type

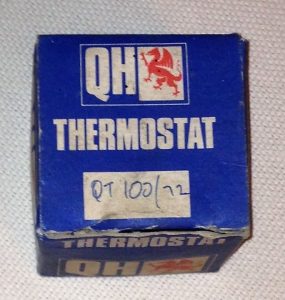

Survey of Quinton Hazell and/or Quinton Brivec

Examples of Quinton-Brivec thermostat and typical box design with Welsh Dragon

Examples of Quinton-Brivec thermostat and typical box design with Welsh Dragon

Initially marketed under the Quinton Brivec brand ( located in Colwyn Bay, Wales and a divison of Quinton Hazell); see photos above. These thermostats had a special Quinton Brivec packaging showing the Welsh Dragon. Later the company brought the packaging under the Quinton Hazell brand (with a smaller Dragon). The code numbers are (more or less) identical for early and later packaging versions.

Quinton Hazell QT 100/200 series

Type QT 100/70, QT 100/72 and QT 100/74

These are bellows-type thermostats (including sleeve) with an opening temperature of 70°, 72° and 74° C respectively.

QT 100/72 in original Quinton Hazell box

QT 100/72 in original Quinton Hazell box

Type QT 200/80 and QT 200/86

Opening temperature: 80 C (176 F) and 86 C (187 F) winter thermostat. With the correct sleeve.

Type QT 200/80 or WT 200/80 (for “winter” thermostat?)

Type QT 200/80 or WT 200/80 (for “winter” thermostat?)

Survey of Remax thermostats

Remax of London had been established in 1928, manufacturing and supplying mechanical (precision) replacement parts for automobiles. After WW2 the company added Automobile Electrical Companents to their portfolio. Thermostats must have been a later addition to the sales programme, probably from the late 1960s onwards.

There is a strong resemblance between the Quinton Hazell and the Remax thermostats, which may lead to the conclusion that QH (or better Quinton Brivec) was their thermostat supplier. Even the type coding was almost identical: where QH refers to QT100 thermostats, Remax opted for NT100.

Remax NT100/68 thermostat has an opening temperature of 68 C.

Remax NT100/68 thermostat has an opening temperature of 68 C.

GH thermostats (most likely made by Quinton Brivec)

Another UK brand named GH has been reported with bellows thermostats that have a large ressemblance with the afore mentioned thernostats as made by Quinton Brivec. There is very little information about the GH company.

The photos below show their type A70 with a 156 F or 70 C opening temperature. Also note their dedicated packaging branded GH.

GH thermostat box Top side is tamped 156 F and 70 C

GH thermostat box Top side is tamped 156 F and 70 C

Bottom side is identical to other Quinton Brivec types but stamped GH

Bottom side is identical to other Quinton Brivec types but stamped GH

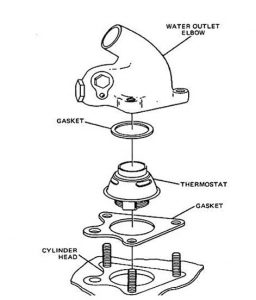

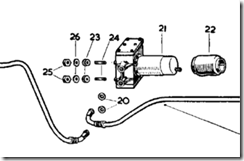

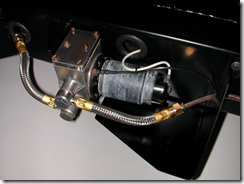

Mounting position of thermostats

All thermostats described in this article have a small hole in the valve. The thermostat should be positioned such that the small hole is always on top, to allow air (bubbles) to escape from behind the thermostat during the refilling process.

Small hole correctly positioned at top (XK 140)

Small hole correctly positioned at top (XK 140)

Non screen bellows-type thermostats

Although a “bellows-type” thermostat, this version has no screen around the bellows to block the water opening like the original version and is not recommended for the earlier XK engines. They have been supplied by Smiths, AC and Quinton Hazell. In reverse it is, however, possible to use the earlier “bellows” type with screen (e.g. C3731/1) on the later engines.

Smiths 85032/70 and /80, 85035/78

Available with opening temperature of 70° C (158 F), 78° C or 80° C (176 F) and others.

Smiths (non-screen) 85035/78 in 2nd generation “Superstat” box

Smiths (non-screen) 85035/78 in 2nd generation “Superstat” box

AC (DELCO) TC range of thermostats

AC-DELCO had a large range of bellows thermostats without a screen. The programme comprises the following types:

- TC1 – 80c

- TC2 – 72c

- TC3 – 80c

- TC4 – 77c

- TC5 – 86c

- TC6 – 72c

- TC7 – 72c

- TC8 – 80c

- TC11 – 80c

- TC12

- TC14 – 80c

AC thermostat of the “non-screen” TC type Still available but incorrect

AC thermostat of the “non-screen” TC type Still available but incorrect

Quinton Hazell QT 101 and 201 series

Available as QT 101/70 and QT 101/80 with opening temperature of 70° C (158 F) or 80° C (176 F). Also QT 201/86 is available as a “winter thermostat”.

QT 101/72 QT 101/80 QT 201/86

New aftermarket thermostat with sleeve: correct type!

Recently some suppliers introduced a correct type of bellows thermostat with sleeve. This version is apparently intended for the MGA, but looks to fit Jaguar XK’s as well. This is an almost exact copy of the original thermostats and functions correctly.

Perfect copies. (Photo courtesy Bob Richards)

Perfect copies. (Photo courtesy Bob Richards)

New aftermarket thermostat with sleeve: incorrect type!

The sleeve of this aftermarket thermostat (above LH) is positioned just below the upper fixation of the thermostat whereas with the original version (above RH) the sleeve is positioned at roughly 25 mm (1 inch) lower.

This type of thermostat (without the extra ring soldered to it) had been invented and produced by the Robertshaw company until about 1999. The extra brass ring has been added to the thermostat by a distributer who modifies the thermostat for use in ‘British’ applications.

At the above photo (courtesy Robert B.) we see that the by-pass opening just below the surface is open when the thermostat is closed. This implies that the coolant remains within the engine to shorten warming-up time. When the thermostat commences to open the screen moves upwards (to the right on the above photo) and gradually shuts the by-pass. Coolant now flows from the engine to the radiator only. In case of the aftermarket type used in a Jaguar XK engine, the by-pass is blocked by the screen meaning it will take much longer before the engine gets warm.

In addition, early XK engines have a “mixture enrichement device” for cold starts. The time during which extra fuel is supplied to the engine is controled by an “Otter switch” that will stop the enrichement the moment the cooling fluid reaches a temperature of about 35C at the position of the Otter switch. It is evident that when the by-pass is not closed, it will take much longer before the mixture enrichement period will be ended. A too rich mixture lead to inregular running of the engine (and does certainly not contribute to a better environment!).

All other bellows or wax-type thermostats without a proper screen will warm-up quicker than the above “after market type”, but the by-pass will remain open at all times meaning a part of the coolant-flow remains within the engine and will not pass through the radiator. The use of these types of thermostat normally results in a higher coolant temperature!

XK’s cooling system conversions

Early XK engines had a cooling system pressure of about 4 lbs./sq.in. Newly developed engines in the 60’s had an increased cooling system pressurization (of at least 7 lbs./sq.in.) and the higher system pressure negatively affected the functioning of the bellows type design as it relied on expanding gases within the bellows.

So in case you have modified your cooling system (and increased the pressure), it is advised to replace the bellows-type thermostat for a wax-type thermostat. Fitting a separate blanking sleeve (that blocks the by-pass) would be an option to compensate for the absence of the sleeve. This may overcome the coolant temperature-rise that normally results from using a “non-sleeved” bellows thermostat.

![clip_image002[4] clip_image002[4]](https://www.bobine.nl/jaguar/wp-content/uploads/2013/08/clip_image0024_thumb.jpg)

![clip_image002[6] clip_image002[6]](https://www.bobine.nl/jaguar/wp-content/uploads/2013/08/clip_image0026_thumb.jpg)

![clip_image002[8] clip_image002[8]](https://www.bobine.nl/jaguar/wp-content/uploads/2013/08/clip_image0028_thumb.jpg)

![clip_image002[4] clip_image002[4]](https://www.bobine.nl/jaguar/wp-content/uploads/2013/06/clip_image0024_thumb1.jpg)

![clip_image002[6] clip_image002[6]](https://www.bobine.nl/jaguar/wp-content/uploads/2013/06/clip_image0026_thumb.jpg)

![clip_image004[6] clip_image004[6]](https://www.bobine.nl/jaguar/wp-content/uploads/2013/06/clip_image0046_thumb.jpg)

![clip_image006[7] clip_image006[7]](https://www.bobine.nl/jaguar/wp-content/uploads/2013/06/clip_image0067_thumb.jpg)

![clip_image004[4] clip_image004[4]](https://www.bobine.nl/jaguar/wp-content/uploads/2013/06/clip_image0044_thumb1.jpg)

![clip_image002[4] clip_image002[4]](https://www.bobine.nl/jaguar/wp-content/uploads/2013/06/clip_image0024_thumb.jpg)

![clip_image004[4] clip_image004[4]](https://www.bobine.nl/jaguar/wp-content/uploads/2013/06/clip_image0044_thumb.jpg)

![clip_image002[4] clip_image002[4]](https://www.bobine.nl/jaguar/wp-content/uploads/2013/05/clip_image0024_thumb2.gif)

![clip_image002[6] clip_image002[6]](https://www.bobine.nl/jaguar/wp-content/uploads/2013/05/clip_image0026_thumb1.gif)