“Loud and Clear”

Lucas High Frequency Horn HF1748 on Jaguars: 1953 to 1961

Original unrestored Lucas HF1748

Original unrestored Lucas HF1748

Lucas High Frequency (HF) horns: short history

In the 19th century Joseph Lucas was a well-known British manufacturer of bicycle parts and accessories (including bicycle bells) that started manufacturing car horns in an early phase of the “new era of motorized transportation”. In about 1890 Lucas introduced a “horn with rubber ball” which in fact was an air horn.

1923 Lucas advertisement 1926 advertisement with Lucas’ first electrical horn

1923 Lucas advertisement 1926 advertisement with Lucas’ first electrical horn

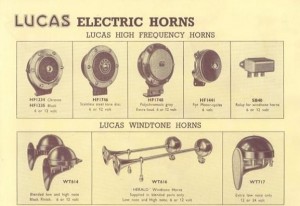

The first electrical horn made by Lucas was introduced around 1925. From 1930 onwards they manufactured also so-called “High Frequency” (HF) horns: several versions in different sizes became available during the Thirties and Forties. Some became very popular like the Alto and Altette, and both have been extensively applied on both motorcycles and cars.

1920’s Lucas brass car horn 1931 Lucas advertisement first generation HF horns

1920’s Lucas brass car horn 1931 Lucas advertisement first generation HF horns

After the war a number of the older types were continued until in 1950/1951 Lucas launched a complete new generation of HF horns consisting of three ranges: HF1746, HF1747 and HF1748. The latter became the most popular version by far and has been used by Jaguar over many years. The HF1748 will be further discussed in this article.

1953 Lucas “Overseas Service Catalogue” shows both HF1746 as HF1748 version but not HF1747

Information on the introduction of the HF1748:

The very first car to have the new HF1748 horn is most likely the Jaguar XK120C (or “C-Type”) in spring 1951. The three Jaguar “Works” Le Mans cars (XKC 001/002/003), the development of which started late 1950 and manufactured and tested early 1951, had one single (low note) HF1748 horn painted black (wrinkle finish), and not grey as with all later Jaguars with this type of horn. This was mounted near the fuse box at the RHS of the scuttle.

“Works” Jaguar (probably XKC 002) with first Lucas HF1748 horn in black

The very first production car with the new HF1748 horn (also with low note and in black wrinkle finish) is most probably the Bentley Mark VI (4½ liter) manufactured and supplied in the autumn of 1951 for export markets. This horn had Lucas part number 70067A and we may assume that this is the same horn as used by Jaguar on the XK 120C Works cars.

Bentley with HF1748

Bentley with HF1748

Jaguar used the HF1748 in production from 1952 until about 1961. Interesting to see that a so-called “Wind Tone” horn (Lucas type WT29U) was the predecessor of the HF1748 in Jaguar’s production and that another “Wind Tone” horn (Lucas type WT618) succeeded the HF1748 from about 1960. It remains unclear why Lucas ceased production of the HF1748 in 1961. Only special (military) versions were continued and years later in 1966 another production run for service reasons.

Principle of HF horns

Electrical horns consist of a steel diaphragm attached to an iron armature; this assembly is placed in a magnetic field generated by a copper coil wounded around an iron core.

Steel diaphragm complete with iron armature (note original color)

The current through the coil generates a magnetic field that attracts the armature + diaphragm against the core. At the moment the armature hits the core, contact points are opened and the magnetic field collapses. This causes the points to close again after which the cycle starts all over. Thus the diaphragm starts to vibrate (about 300 to 400 x per second) causing sound waves that we can hear. Normally electrical horns have a sound level of more than 100 db.

There are two basic types of Lucas horns:

“Wind Tone” horns amplify sound waves using a “trumpet” of specific length, related to the wave length of the sound. These “trumpets” can be both straight or “spiraled” in order to keep the horn compact in size. Lucas examples are the aforementioned types WT29(U) and the later WT618.

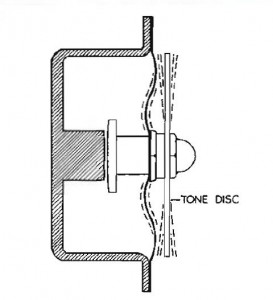

“High Frequency” horns are based on a different principle: every time the armature (+ diaphragm) hits the core, a special “Tone Disc” (firmly attached to the diaphragm and having a specific calculated “natural frequency”) gets into a “higher harmonic” resonance.

Principle of a High Frequency horn Special “Tone Disc” at the front of a HF 1748 horn

Principle of a High Frequency horn Special “Tone Disc” at the front of a HF 1748 horn

Lucas HF1748 horns can be obtained as either “High Note” or “Low Note” version. It is in fact the construction of the diaphragm that determines whether we’ll have a high or low note, and not the tone disc which is the same for both versions. The results is a sound of 300 to 400 Hz, combined with the higher harmonics of these frequencies , leading to a penetrating yet pleasant sound. As mentioned, the material choice and construction of the Tone Disc are crucial, as is the fixation of the Tone Disc to the diaphragm. Lucas used a specific aluminum alloy for the Tone Disc.

Because the powerful sound of the HF horn is generated by using an additional resonance of the Tone Disc, it will be clear that other vibrations in this construction have to be prevented as they may affect the resonance. It is therefore of the greatest importance that the HF horn is firmly attached to a “solid” part of the car.

Survey of Jaguars with Lucas HF 1748 horn

1. Jaguar XK 120C (or C-type)

As mentioned in the introduction, the application of HF1748 horns started with the Jaguar XK 120C (or C-type) in 1951. These first horns were black (as later applied by Bentley and Rolls-Royce). The photo in the British magazine Autocar of July 13, 1951 clearly shows a black HF1748 mounted on the scuttle of a “Works” XK120C. This is further supported by a photo at page 132 of the book “Jaguar Sports Racing & Works Competition Cars to 1953” by Andrew White. A year later another British magazine “Motor” in their “Road Test” of October 22, 1952 shows a HF 1748 on a later XK120C (the so-called “Production” models) which now have a grey color as will be the case for all later Jaguars.

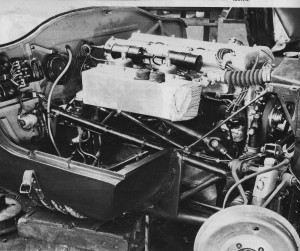

Recent photo of the 1952 C type XKC 045 with single HF1748 at the RH side (note the SU H8 carburetors!)

Recent photo of the 1952 C type XKC 045 with single HF1748 at the RH side (note the SU H8 carburetors!)

Recent photo of Jaguar XKC 053 with single HF 1748 (moved to LH due to installation of “cold air box” for triple Webers)

Recent photo of Jaguar XKC 053 with single HF 1748 (moved to LH due to installation of “cold air box” for triple Webers)

2. Jaguar XK 120

Although never mentioned in the XK 120 Jaguar Spare Parts Catalogue, according Lucas catalogue 400D of 1954 and 400E of 1960, the Jaguar XK 120 did have two Lucas HF1748 horns (Low Note and High Note) in 1953 and 1954, however only on DHC and FHC versions manufactured for export. See also the remarks made for the Mark VII here below.

3. Jaguar Mark VII and VII M

According Lucas catalogue 400E of 1960, but also mentioned in Jaguar Service Bulletin Nº 129 of August 1953, the Jaguar Mark VII had two HF1748 horns from chassis number 716017 (RHD) and 736522 (LHD) manufactured from 1953 onwards. These Lucas horns had part number 70063B fort the low note version and 70071B for the high note. According the Lucas catalogue the application of these horns was initially limited to Export versions of the Mark VII during 1953 and 1954. Thereafter all Mark VII versions had these horns until 1958.

Jaguar part numbers C.5226 and C.5227 have been mentioned fort the first time in the above Service Bulletin. This early part number may indicate that the Lucas HF1748 had become part of the Jaguar part stock in 1952 or 1953.

The thesis that HF1748 horns have also been applied by Jaguar on the XK120 from 1953 onwards is further supported by the fact that the horn relay (as used for the WT29U Wind Tone claxon) is only mentioned during the period 1951 till 1953 and no longer thereafter. The HF1748 (in 12 Volts execution) does not require a horn relay as the maximum current is only 4 Amps whereas Wind Tone versions have a maximum of 6 to 7 Ampère. A complete set of Wind Tone horns may draw up to almost 15 Amps and Lucas even prescribed the use of a 50 Amp fuse in the supply of the horns.

Correct HF1748 brass type plates from 1953 for Mark VII or XK 120; note the non-uniform way of date code stamping!

Correct HF1748 brass type plates from 1953 for Mark VII or XK 120; note the non-uniform way of date code stamping!

4. Jaguar XK “D-type”

There is no hard written data available from either Jaguar nor Lucas, whether the D-type actually had the HF1748 as standard equipment, but there is sufficient “physical” evidence that they had a single Lucas High Frequency horn. This is further supported by the fact that the XK-SS of 1956 (using the remaining unsold D-type cars) actually had one single HF1748 High Note horn (see paragraph 7).

HF1748 behind the radiator on a D-type

HF1748 behind the radiator on a D-type

5. Jaguar XK 140

From the introduction in 1954 the Jaguar XK 140 had HF 1748 HF horns until the end of production in 1957. Jaguar had already assigned part numbers C.5226 and C.5227 for (resp.) the High Note and Low Note version. The Lucas numbers now had a different suffix: 700071D and 70063D (resp.).

Original Lucas type plate for XK 140 or later Mark VII

Original Lucas type plate for XK 140 or later Mark VII

6. Jaguar XK 150

The Jaguar XK 150 continued the use of the HF1748; the XK 150 Spare Parts Catalogue simply copied the part numbers of the XK140, although Lucas had meanwhile changed the suffix in 1956 from D to E and in 1958 again from E to F. This information for owners who absolutely need the correct part numbers for their cars!

7. Jaguar XK-SS

The open 2-seater on basis of the D-Type Jaguar had in 1957 (just like the C-Type some years before) one single but now High Note HF1748 horn with Lucas number 70071/E.

8. Jaguar Mark 1 and 2

Also the Jaguar Mark 1 (both 2.4 and 3.4) had the Lucas HF1748 from production-start. The part numbers over the period 1955 to 1959 are identical to those from the XK140 and XK150 as described above.

The Jaguar Mark 2 (all engines: 2.4 , 3.4 and 3.8) had from October 1959 till September 1960 the HF 1748 as standard version.

9. Jaguar Mark VIII and IX

As successors to the Mark VII (M) models, the Jaguar Mark VIII and IX continued the use of the Lucas HF 1748 from 1957 to 1960 with Lucas numbers 70063E or F and 70071E or F until production ceased early 1961.

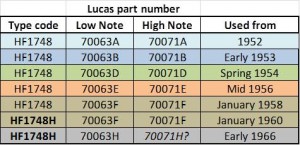

Lucas HF1748 part numbers and date codes

It is interesting to look at the part number sequence as assigned by the Lucas development group in 1951 to the various versions of the HF1748 and their respective introduction dates. We may conclude from this list that part numbers have apparently been “reserved” for applications that started only some years later. A survey of Lucas part numbers:

- 70062 6 Volt Low note Grey Unknown (motorcycles)

- 70063 12 Volt Low note Grey 1953

- 70064 24 Volt Low note Grey Unknown (lorries/trucks)

- 70067 12 Volt Low note Black 1951

- 70070 12 Volt High note Black 1952

- 70071 12 Volt High note Grey 1953

- 70073 24 Volt Low note Green 1952 (military)

- 70079 6 Volt High Note Grey Unknown (motorcycles)

The 1954 Lucas catalogue van 1954 lists the part numbers for the different HF1748 horns produced in black and grey. Jaguar only used the “polychromatic” grey version which had initially Lucas number 70063 for the low note and 70071 for the high note version. Although the Lucas 1954 catalogue does not provide any suffix letter, we know that in 1953 the suffix B and in 1954 the letter D was used. Apparently suffix C is not used by Lucas.

In addition there is also the Lucas number 069448 for the 70063 low note horn. This particular part number was already used for the 1954 Austin A30. Jaguar kept on using the Lucas numbers 70063/D and 70071/D in their catalogues up to 1961 although Lucas had meanwhile officially changed the part number for supplies to Jaguar in resp. 069448 and 069474. We have to assume that 0694xx numbers have been assigned to “assemblies” that consist of the original part plus a number of additional items required for (e.g.) installation. These 0694xx numbers have been used by Lucas for other horns as well from 1953/1954 onwards.

The black version of the HF 1748 with Lucas part numbers 70067 and 70070 for the low note and high note version, however, has always kept these numbers as there are no examples of 0694xx numbers for these horns.

If you would like to use the correct Lucas HF1748 type plate (or tag) for your car, the survey below might help you. Note that the Lucas type indication HF 1748 was changed (for reasons unknown) in 1960 to HF 1748H.

Survey of part numbers over the years

Survey of part numbers over the years

After production ceased Lucas provided Factory Rebuilt Units that received an H date code. An example manufactured in March 1965 is shown below.

Factory Rebuikt Units

Factory Rebuikt Units

Lucas 1748 horns in detail

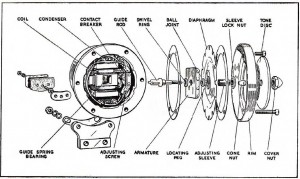

Exploded view of HF1748

Exploded view of HF1748

The “exploded view” above shows the construction of the HF1748. The mechanical differences between the high and low note version only relate to the steel diaphragm: Lucas part number 703726 for the low note and 703727 for the high note version. It is therefore absolutely possible to change a low note into a high note horn just by changing the diaphragm.

Repairing/restoring a Lucas HF1748 horn

If a HF1748 does not function well any more (or not at all), it is in most cases possible to repair or restore but this will depend on the overall condition of the horn. Just turning the adjuster screw at the back will not cure the problem, unfortunately!

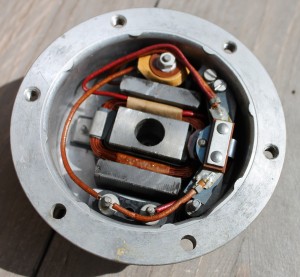

The inside of a 60 year old HF1748 can look like this!

The inside of a 60 year old HF1748 can look like this!

But also like this: corroded beyond repair!

But also like this: corroded beyond repair!

There are 60 year old examples that look still immaculate inside, but there are also cases where it looks as if the horn has been submersed in seawater for decades and are corroded to a degree that nothing can be saved! The aluminum outer rim is particularly fragile and might show cracks or has been completely disintegrated; welding of this zinc-aluminum alloy is (almost) impossible.

Lucas stopped the supply of service parts for these HF horns many decades ago. There are some specialist companies that may have some parts while others have remanufactured small batches of the most “popular” parts like e.g. the outer rim, the tone disc and the paper gaskets. The mounting bracket (Jaguar 3502, Lucas 704651) can still be ordered from most Jaguar part suppliers. Note that there is also an almost identical Bracket 690617 as used for the Lucas Wind Tone horns type WT29(U) and WT618, but the dimensions are different and it will not fit the HF1748.

Original Bracket for HF1748; still available

Original Bracket for HF1748; still available

In most cases parts have to be reused and missing parts have to be taken from another horn or made new. The outside of all Jaguar HF1748 horns have been painted grey. This color (Lucas reference: “polychromatic grey”) however changed somewhat over the years (darker/ lighter). The term polychromatic is used for the first generations of “metallic” paint however with different and far less metal flakes than is used today. The original Lucas versions have been completely painted in grey, meaning also screws and brass parts are grey. Some owners like the looks of polished brass parts: the cover nut and type plate are shining “like new”, but remember that Lucas delivered them only covered with grey paint. The diaphragm is sometimes painted grey and sometimes black, but I’ve even seen grey painted over black.

Reproduction outer rim, now made from a stronger aluminum alloy!

Adjustment of HF1748 horns

After a complete restoration, a number of settings require adjustments. This assumes some “craftsmanship” and specific tools and measuring equipment. The procedure in short:

All parts should be checked for defects and repaired where required, before they can be re-used (or not..). The contact breaker points have to be cleaned in a similar manner as with your ignition points. Check the continuity of the various electrical components and circuits with a suitable “multi meter”. The capacitor (condenser) can also be defective after 60 years or may have developed an earth leak. Note that later production (1966) had a “modern” capacitor (15 µF ± 10% 500V DC) which can now be used for replacement and is available from any good electronics specialist.

Later type of capacitor

Later type of capacitor

A logical consequence of the difference in “stiffness” of the low and high note diaphragm is that the maximum amplitude of the two diaphragms have to be set differently, in order to obtain the maximum resonance of the tone disc. The maximum amplitude of the vibration is determined by the air gap between the armature and coil core. The Low Note version requires an air gap of about 0.025” (or 0.6 mm) and the High Note has a shorter distance of about 0.020” (or 0.5 mm); both values for 12 V versions only.

To adjust the air gap, the “Adjusting Sleeve” (see Exploded View) should be turned in or out until the correct value has been obtained. To do so, first screw the Adjusting Screw at the back of the horn a number of turns in clockwise direction in order to fully close the contact points: the armature will now rest on the core if the circuit is connected to 12 V. Use a clock dial to measure the distance in the center of the diaphragm. Don’t continue the power to the horn for too long as the coil may become (too) hot. When the correct air gap has been obtained , the contact breaker has to be adjusted with the Adjusting Screw at the back until a loud tone is heard. The same screw is used for setting the maximum current which should be about 4 Amps max. Now your horn should function “Loud and Clear”.

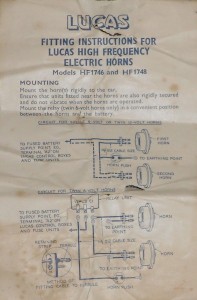

Fitting instructions leaflet for HF1748

Fitting instructions leaflet for HF1748

Other related Lucas HF horns

There are two versions that have to be mentioned here:

I. The first is a special military version of the Lucas HF1748 as used by Daimler on their Ferret Scout. This military armored reconnaissance vehicle used by the British Army was produced from 1952 till 1971. It was a 24 Volts HF1748 horn in a green color. The Lucas part number is 70073 (+ suffix) but the type plate also mentions the Daimler code FV.157950. Apart from the (24 V) coil and color this horn is identical to the HF1748 as described above.

Military version HF1748 Daimler Ferret Scout Note special

Military version HF1748 Daimler Ferret Scout Note special

Special Daimler type plate for Military version

Special Daimler type plate for Military version

II. The HF1746 is a “weather resistant” version of the HF1748 specially made for “exposed” installation e.g. at the front of a lorry or motorcycle: some parts have been made of stainless steel or have been chromed.

Lucas HF1746 requiring a full restoration Original Lucas HF1746 in box

Lucas HF1746 requiring a full restoration Original Lucas HF1746 in box

Other British cars with Lucas HF 1748 horn(s)

- Aston Martin DB3/S (1956) with Lucas 70063/D and 70071/D.

- Austin A30 (1954) with single Lucas 70063/D.

- Austin A40 and A50 “Cambridge” (1955) with 70063/D and 70071/D.

- Austin Healey “100”, “100M”, “100 Six” and “3000” from 1954 to 1960 with 70063 and 70071.

- Bentley Saloons (1951 to 1955) had Lucas 70067 and 70070 in black.

- Cooper “Monaco” Sports (1959 to 1960) with single 70063/F.

- Rolls-Royce “Silver Dawn” and “Silver Wraith” (1953 to 1959) with 70067 and 70070 in black.

Hello,

Very good article. One correction for you. The tone disc is made of magnesium, not aluminum. I made one from aluminum and was surprised to find it a fair bit heavier than an original disc. Took one into work and had it tested in a SEM. Almost pure Mg.

I just restored a pair 70063E, and missing tag from the other. I am very happy to find such a deep immersion on the history and numbers of these horns. AMAZING! Thank You. I am printing a copy of this for my customer. I was able to adjust both to a clear harmony voice that I am sure my customer will appreciate. YES, I could have used the replacement LUCAS cowlings, and was not surprised to find English thread configurations- that I replaced with Stainless Steel cheese head fasteners polished to a high luster, and acorn nuts on the back side–as threads were eroded away. Nice looking workaround! Now only missing the partner horns name tag. I will just stamp one out!