Crankshaft Torsional Vibration Damper Assemblies for XKs

Background information

Certain high speed in-line internal combustion engines are prone to torsional vibration of their crankshafts: the straight six and straight eight engines being particularly prone to this problem due to their long crankshaft length. A crankshaft vibration damper is required for which two basic concepts are applied: the frictional vibration damper (e.g. RR and Bentley) and the rubber bonded damper.

The Metalastik factory in Leicester (UK)

The Metalastik factory in Leicester (UK)

Mac Goldsmith (Max Goldschmidt) started his engineering company near Frankfurt (Germany) in 1925. He moved to England in 1937 and formed the Bundy Tubing company in Welwyn Garden City (north of London), manufacturing copper coated tubing. About a year later he established the Metalastik company in Leicester. Another famous Leicester rubber manufacturer, the John Bull Rubber Company, merged with Metalastik Precision Rubbers in 1955. In 1958 the group became part of the Dunlop Rubber Company Ltd. The Metalastik trademark is still used today by its new owner Trelleborg.

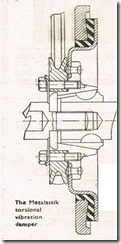

In the late thirties the Metalastik company introduced an improved and simpler design which is the rubber bonded metal disc type and this remained standard on many engines to this day. The Metalastik type is not just a damper, but rather a tuned and damped ‘vibration absorber’. The vibration absorber is a secondary inertial mass and spring stiffness, tuned to the first natural torsional frequency of the crankshaft assembly; this results in two new natural frequencies, one above and one below the tuned frequency, and a marked reduction in the amplitude of oscillation of the crankshaft at the original natural frequency. The inherent damping of the rubber ensures that the amplitude of oscillation of both the crankshaft and the absorber at the two new natural frequencies are within acceptable limits.

The 3442 cc Jaguar XK 6-cylinder engine of 1948 and most subsequent versions of the Jaguar XK engine used a proprietary Metalastik vibration damper to protect their crankshafts from potentially damaging torsional vibrations. To quote William Heynes in 1953, “The Metalastik damper consists of a steel plate to which is bonded, through a thick rubber disk, a malleable iron floating weight. Variations of the weight, rubber volume and mix, give these dampers a very wide field over which they can operate.”

The rubber bonding of the original Metalastik dampers is prone to disintegration through age and oil contamination. The rubber compound hardens and breaks up, which means that the damper is no longer absorbing crankshaft vibrations. Jaguar advises a deflection of the damper weight in relation to the crankshaft of no more than ½°; the torsional vibration damper should be renewed when the deflection is more than this figure.

Oct ’53 advertisement 1957 advertisement with cross section of vibration dampers (top LH)

1959 Metalastik advertisement: note picture of Jaguar damper and related text

Survey of XK crankshaft dampers

All XK 120/140/150 crankshaft dampers have been manufactured by Metalastik of Leicester, UK (since 1958 part of the Dunlop group). Most (all?) of the dampers have the following text stamped on the back (engine side) of the damper: METALASTIK PATENT T.V. DAMPER PART Nº 51/XXX whereby the last three numbers indicate the specific version. The abbreviation T.V. stands for “Torsional Vibration” damper.

Configuration of Metalastik dampers

The basic design of the Metalastik damper of the 51 series consists of a stamped dish of ⅛” steel (8” outer diameter, about 3½” inner diameter and a recess/depth of about ⅞”) to which a cast centre spigot for the damper-cone is riveted (12 rivets). The “floating weight” (or inertia disc) is bonded by thick rubber to the aforementioned steel dish. The material of the floating weight (9” outer diameter) varied over the years: cast iron, malleable cast iron and steel were used depending on the type of XK engine.

Two basic types used for XK’s

Metalastik manufactured three basic types for Jaguar (but also used by others like e.g. Austin Healey and Maserati). All crankshaft dampers with a cast iron or malleable cast iron weight (about ½” thick) were coded 51/177. The versions with a steel weight (⅜” thick) suitable for higher rev’s, were coded 51/211. Note that there was a third damper version coded 51/227, but these were only applied on 2.4 ltr engines and therefore never used on XK’s.

Over the years small changes have been made in particular related to the timing marks on the floating weight, but the Metalastik code number remained unaltered. Jaguar, however, changed the part number with every (minor) change, making it rather difficult to determine (more than 60 years later) what the corresponding Jaguar part number is for a particular Metalastik version.

1. Crankshaft dampers for Jaguar XK 120

1.1. Introduction engines 1948

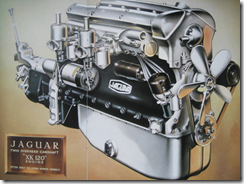

First photos and drawings presented during the introduction of the XK engine in 1948 show an engine without a damper fitted to the crankshaft.

1948: without crankshaft damper

1948: without crankshaft damper

1.2. Jaguar part nº C2464 (Metalastik Part Nº 51/177)

From engine Nº W1001 (October 1949) to W8306 (May 1953) a Metalastik damper with a cast iron floating weight had been installed. The edge of the floating weight casting measures about 13.5 mm over 6.3 mm whereas the rest of the weight measures only 9.5 mm (see drawing with cross section of damper). Outer diameter of the floating weight is about 9” and the inner diameter 6¼”. There are no timing marks on the damper. This version was used until May ‘53.

C2464 damper Cross section (October 1953)

C2464 damper Cross section (October 1953)

Part Nº 51/177

Part Nº 51/177

1.3. Jaguar part nº C5809 (Metalastik Part Nº 51/211)

June 1951 saw the publication of the famous Service Bulletin 95 which gave a survey of the “Tuning Modifications on XK 120 cars for Competition Purposes”. Next to a lightened flywheel a “Special Crankshaft Damper Part No. C5809” was introduced which was “specially tested for operation at high rpm”.

In comparison to Part Nº C2464 the floating weight was made of steel instead of cast iron, apparently better coping with the continuous higher revs at which these dampers were run (maximum engine output now at 5800 rpm instead of 5400 rpm). The floating weight in steel measures only ⅜” (or 9.5 mm) instead of 1/2″ (or 13 mm) of the cast iron version, which relates to the difference in specific gravity. This crankshaft damper used a special rubber mix for the bonding of the steel weight. The Metalastik Part Nº 51/211 had the mark “COMP” stamped at the front (see photo).

“COMP” stamped at the front

“COMP” stamped at the front

Outer diameter of the steel floating weight measures about 9” and the inner diameter 6¼”. Total weight is about 3.3 kilos.

This damper was used on the following XK 120s:

1.3.1. Earlier and later engines modified for Competition purposes according SB95 replacing the C2464 damper

1.3.2. Engines in Special Equipment (SE) cars from June 1951

1.3.3. Engines Nº W8307 to W8380 (production month May 1953). Apparently the old damper C2464 was no longer available while the successor type C8020 still had to be manufactured. For these 73(?) standard engines damper C5809 was used.

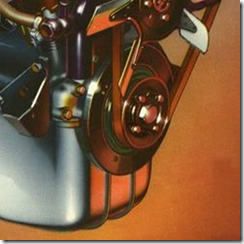

C5809 with crankshaft pulley installed

C5809 with crankshaft pulley installed

1.4. Jaguar part nº C8020 (Metalastik Part Nº 51/177)

From Engine Nº W8381 (May 1953) a new Metalastik damper with malleable cast iron floating weight was used. Metalastik changed from a (grey) cast iron to a malleable cast iron version because of its more ductile characteristics.

The floating weight is about 13 mm thick at the edge. Outer diameter measures about 9” and the inner diameter 6¼”. This damper has no timing marks (or lines) at the front side.

2. Crankshaft dampers Jaguar XK140

2.1. Jaguar part nº C8241 (Metalastik Part Nº 51/177)

Engines with a standard cylinder head received this damper. This part succeeds C8020 meaning a Metalastik damper with malleable cast iron floating weight. By September 1954 this damper received 3 timing marks at 0 – 5 – 10° BTDC without any figures stamped above the marks.

C8241 (cleaned before painting)

C8241 (cleaned before painting)

2.2. Jaguar part nº C8129 (Metalastik Part Nº 51/211)

Used on engines with the C type cylinder head, this damper is similar to damper C5809 meaning the inertia disc was made of steel and used a special rubber mix for the bonding of the weight. As it was a 51/211 version it continued to show the “COMP” mark. It received 3 timing marks (lines) at 0 – 5 – 10° BTDC without any figures stamped above the lines.

C8129

C8129

Note that the stamping on the rear side shows the marking METALASTIKPATENT T.V.DAMPERPARTNº51/211 without any spacing between the words. This in contradiction to the Metalastik 51/177 version where there are spaces between the words and the part number is given in a second line.

For Metalastik the basic design was unaltered and they continued with their part number 51/211. Jaguar, however, changed the part number to C8129 because of the new timing marks. The outer diameter of the damper is 9” or about 230 mm. This damper has a ⅜” or 9.5 mm thick floating steel weight with an inner diameter of about 160 mm. The overall weight of the damper is about 3.3 kilos of which the floating weight takes about 1.5 kilos, meaning 46% of the total weight is in the inertia disc.

3. Crankshaft dampers Jaguar XK150

3.1. Jaguar part nº C8241 (Metalastik Part Nº 51/177)

All 3.4 litre engines from March 1957 onwards continued using the damper of the standard XK 140 engine. See under 2.1. From May 1960 onwards the TDC timing mark was continued on the edge of all dampers to facilitate timing by means of “modern” testing equipment.

TDC timing mark on edge from May ’60

TDC timing mark on edge from May ’60

3.2. Jaguar part nº C15274 (Metalastik Part Nº 51/211)

Late 1959 the 3.8 litre was introduced and received another updated version of the 51/211 crankshaft damper. Basic dimensions remained unchanged but the markings were new.

C15274

C15274

The damper version now had a full timing scale with marks at 0 – 5 – 10° BTDC and the figures stamped above the lines. Smaller markings every degree between 0 and 10°. The TDC timing mark was continued on the edge of the damper. Dimensions remained identical to C8129 and it still carried the mark COMP.

C15274

C15274

4. Later Crankshaft dampers Metalastik Part Nº 51/227

With the introduction of the 2.4 litre engines in 1955 the need arose to develop an optimised version for this (short stroke) engine. Note that Metalastik developed a third range of Crankshaft Dampers with Part Nº 51/277.

Example of the 51/227 series of dampers

Example of the 51/227 series of dampers

There were two 51/227 versions used by Jaguar:

- Jaguar Part No. C12037 mounted on 2.4 ltr. engines of the jaguar Mk 1 and Mk 2 (up to engine No. BJ6131) over the period 1955 up to 1963. These versions had one single timing mark (TDC) on the edge of the damper.

- Jaguar Part C24921 mounted on 2.4 ltr. engines of the Jaguar Mk 2 from engine No. BJ6132 onwards in the period 1964 till 1967. Here, however, the pulley and damper had been integrated.

Photo courtesy of Eric Kriss.

Have sent details of early E-type chassis I.D. plate (875 014) & 2 photos to your e-mail

David

Pingback: Metalastik damper - Jaguar Mk2 Restoration